Subtopic 2: Solution Processed Excitonic Solar Cells

基於柔性機構的卷對卷印刷系統的精密設計及控制

Flexure-based Precision Roll-to-roll Machine for Fabrication of Flexible Electronics

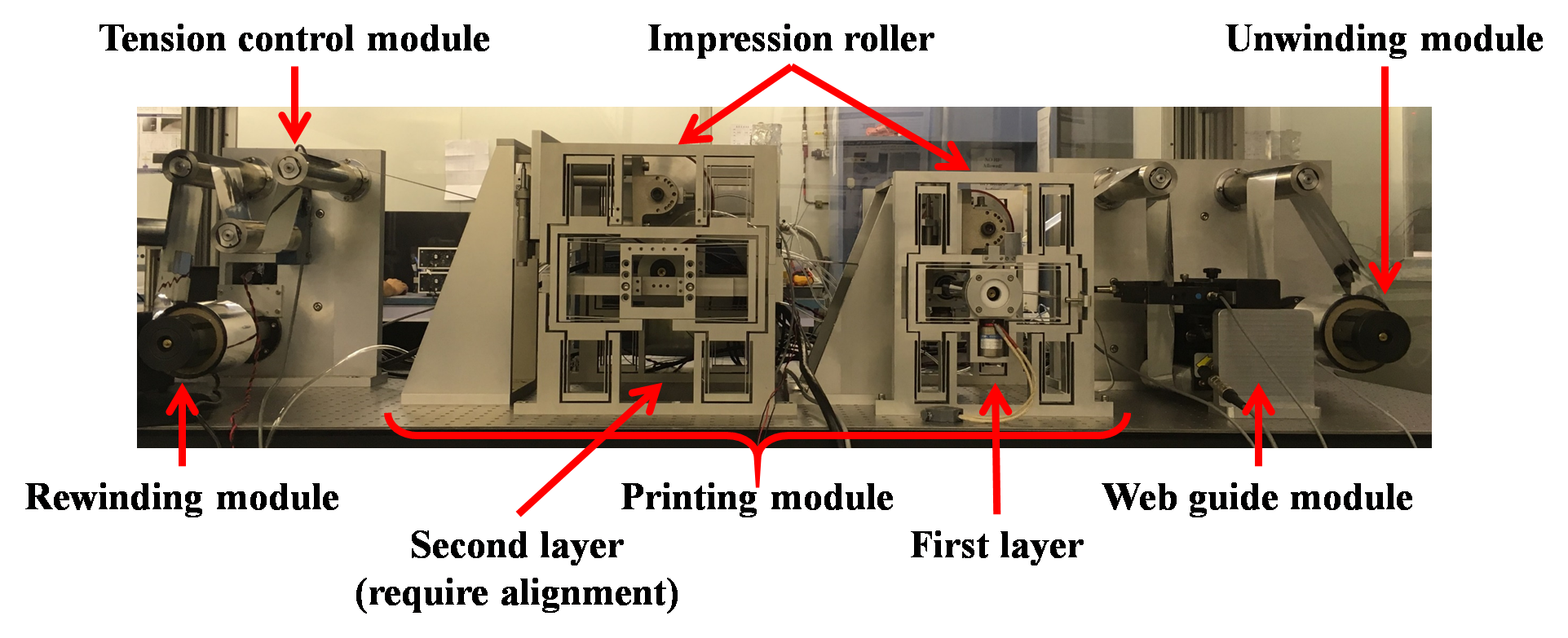

基於柔性機構的多層卷對卷印刷系統原型

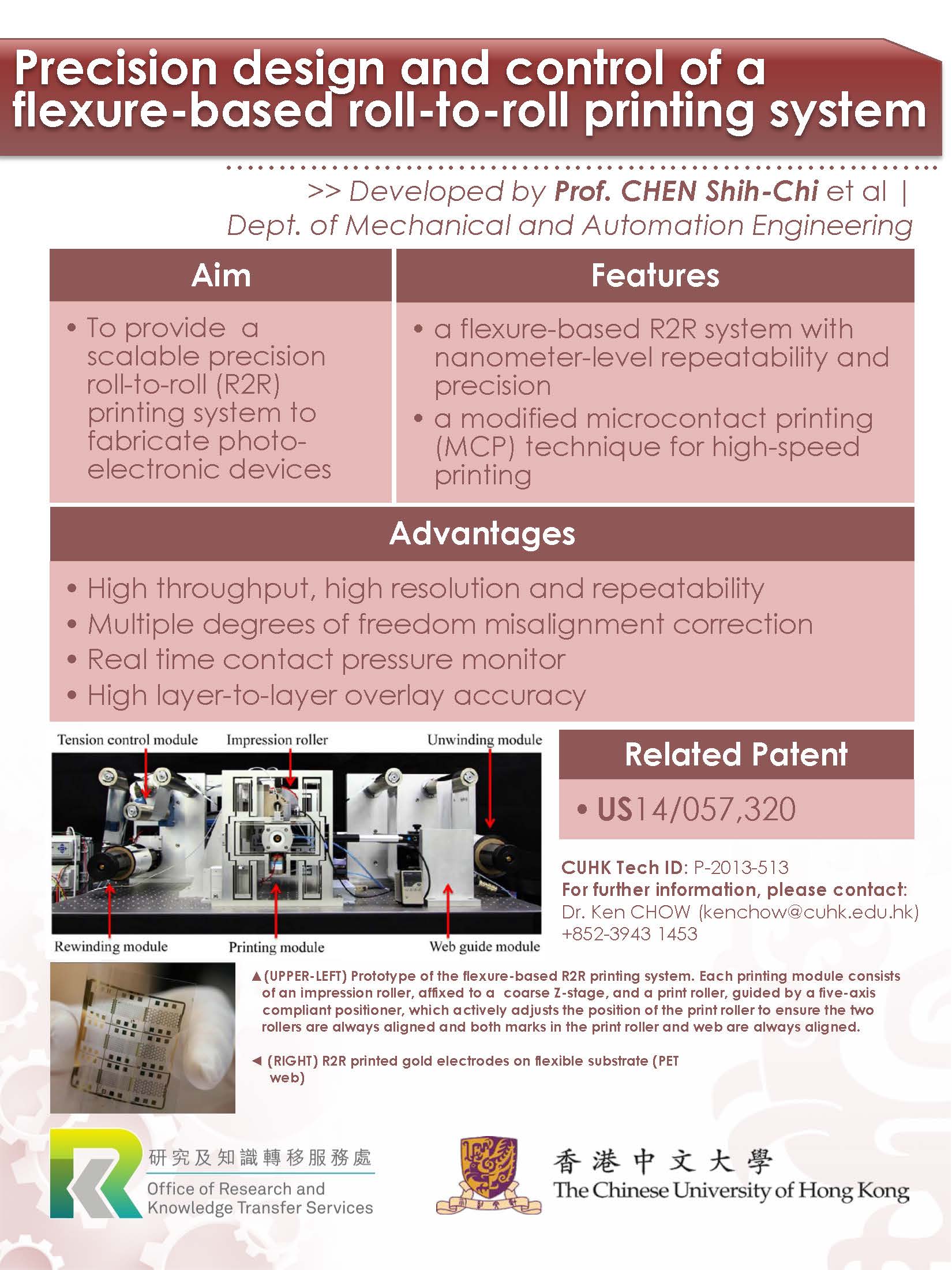

Prototype of the flexure-based multi-layer R2R printing system

在柔性基底上卷對卷印刷金電極

R2R printed gold electrodes on flexible substrate (PET web)

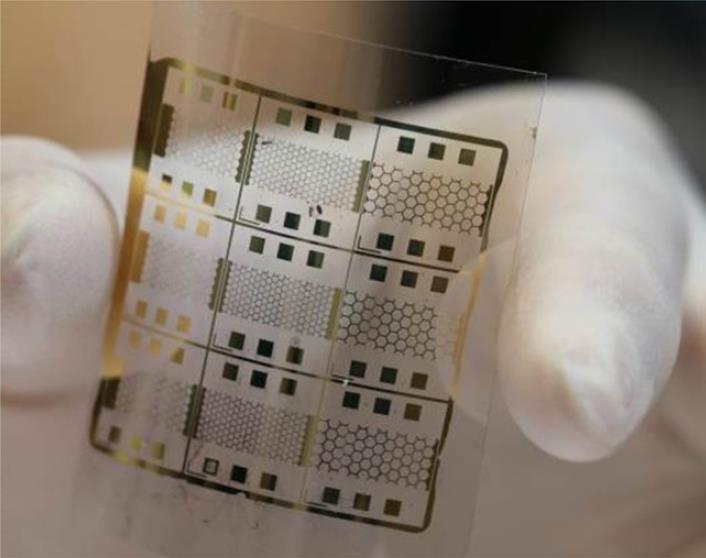

Sample printed products: Flexure-based Precision Roll-to-roll Machine for Fabrication of Flexible Electronics

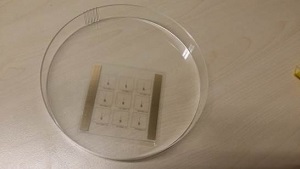

(Left) First Layer of FET (Field-effect Transistor) Fabricated by Roll-to-roll Printing System (卷對卷印刷系統所製造之晶體管的第一層) ;

(Right) Metal Grids Fabricated by Roll-to-roll Printing System (卷對卷印刷系統所製造的金屬網格)

項目說明 Project Description

卷對卷(Roll-to-Roll, R2R)製造技術在許多產業中早已被廣泛應用,例如造紙業、紡織業或是鋼鐵業,其主要特性為連續式、大量生產等,具有簡單、綠色、低成本等優點,故一致被業界認為是未來製造的發展方向。

香港中文大學(中大)機械與自動化工程系副教授陳世祈教授開發了一個以微接觸印刷(MCP)技術為基礎的精密多層卷對卷印刷(R2R)系統,以低成本量化生產高解像度高對準精度的光電器件。微接觸印刷是一種軟光刻技術,實驗證實其印刷精度不受光學衍射極限的限制,可達到納米量級的解像度。目前微接觸印刷僅應用於學術研究,並未應用於實際生產。本項目將開發微接觸印刷的關鍵技術,並將自行研發的高精度微接觸多層卷對卷印刷系統用於量化生產以下兩種柔性光電器件:(1)有機場效應電晶體(2)基於超穎材料的太赫茲吸收體。為開發關鍵技術,團隊將設計並製造以柔性機構為主體,(1)具有納米量級準確度及多軸校準功能,及(2)亞微米量級多層對準精度的高精度滾筒印刷系統。柔性機構已被廣泛的應用於高精度光刻定位設備,此技術將大幅提高多層滾筒印刷系統的可重複性,精度和解像度,並可廣泛應用於製造低成本光電器件。

Roll-to-Roll (R2R) printing technology has been widely adopted in various industrial applications, e.g. paper, textile and steel industries. Its characteristics include continuous printing and high throughput, simplified process, environment-friendly and low cost, hence considered promising in future applications.

The CUHK research team led by Prof. Shih-Chi Chen , Department of Mechanical and Automation Engineering developed a scalable precision multi-layer roll-to-roll (R2R) printing system that achieves continuous printing on a 4” web with 100 nm print resolution. The R2R platform is compatible with various high precision contact printing techniques. For example, Microcontact Printing (MCP) technique has been implemented on the R2R system to fabricate nanoscale photonic devices and optical components, e.g., optical gratings. To demonstrate the practicality, this project will deliver R2R fabricated (1) optical gratings of various pitches, (2) organic field-effect transistors, and (3) terahertz metamaterial perfect absorber. To illustrate the capabilities of the high- throughput high-resolution multi-layer R2R .

The high printing precision of the R2R platform is realized via the application of compliant mechanisms which generate highly repeatable mechanical motion via the compliance of the material. In the R2R system, the print roller is supported by a four-axis flexure positioner; in combination with a cascade feed-forward controller, nanometer level positioning precision is achieved. Multi-layer submicron registration accuracy is achieved via a five-axis flexure positioner with novel optical alignment algorithms. The developed technology could be widely adapted to manufacture low cost photoelectronic devices.

針對問題 Problem to be solved

1:設計並構造一個多軸柔性機構導向的卷對卷印刷系統

2:開發基於柔性機構的多層卷對卷印刷系統

3:開發基於微接觸印刷的亞微米解像度樣本的生產工藝

4:設計和優化生產光柵和金屬網格的工藝參數

5:設計並實現亞微米精確度的多層對準方法

6:將微接觸印刷金屬網格應用於柔性有機光伏電池

1:Design and construct a multi-axis flexure guided R2R system

2:Develop a multi-layer flexure-based R2R printing system

3:Develop process to fabricate submicron resolution samples using MCP

4: Design and optimize fabrication parameters for printable optical gratings and metal grids

5: Design and implement a submicron accuracy multi-layer registration method

6: Incorporation of MCP metal grids into flexible organic photovoltaic cells

特點及優勢 Uniqueness and Competitive Advantages

團隊成功研發全球精確度紀錄最高之卷對卷多印刷技術,準確度達 100 nm,並具有以下特長:

The team successfully developed a world record technology in precision R2R printing, realizing continuous printing on 4” web with 100 nm resolution with the following merits:

1:高解像度及可重複性

2:高產量

3:多自由度誤差校正

4:實時接觸壓力監控

5:層與層之間的高對準精度

1: high resolution and repeatability

2: high throughput

3: multiple DOFs misalignment correction capability

4: real time contact pressure monitoring

5: Submicron layer-to-layer registration accuracy

應用 Applications

此技術已獲兩項美國專利。同時,由於此技術的高精確度,它非常適合應用於製造精密細小及厚度超薄的可彎曲光電器件。如應用此技術,將令體積更細小及厚度超薄的可彎曲光電器件。如應用此技術,將令體積更細小及可穿戴式的各種器件設計變得可能,大大促進新型便擕產品的發展生產。現時,技術已能印製 4 英吋寬度的產品,亦能升級至 1 – 2 米寬度。

其他應用包括:

1:衍射光柵

2:高解像度 ~85%透明的金屬網格

3:以金屬網格為電極的柔性有機光伏電池

4:有機薄膜場效應電晶體

5:光學超穎材料 如太赫茲吸收體

6:多層柔性印刷電路

This technology already obtained two US patents. Owing to its high precision, the technology is very suitable for manufacturing high-resolution and ultrathin flexible electronics and photoelectronic devices. By adopting this technology, the design of more tiny size and wearable devices would become possible, substantially fostering the manufacturing of portable products. Currently, the web width is 4 inch and it is able to be upgraded to 1 – 2 m.

Other applications include:

1: diffraction gratings

2: high resolution ~85% transparent metal grids

3: flexible organic photovoltaic cells that utilize the metal grids as electrodes

4: organic thin-film field-effect transistor

5: photonic metamaterial, e.g. terahertz

perfect absorber

6: multi-layer flexible printed circuit

目標用戶 Target Users

柔性電子/光電子器件產品生產商

Manufacturers of flexible electronics/ photoelectronic devices

專利 Patents

"Roll-To-Roll Printing Systems and Methods for Fabricating Print Roller”, U.S. Utility Patent Application, No. 14/057,320

相關文獻 Related Paper:

- Xi Zhou, Dien Wang, Ji Wang, and Shih-Chi Chen*. (2016). Precision design and control of a flexure-based roll-to-roll printing system. Precision Engineering 45: 332 – 41. [Link]

|

|

| Project Leaflet 研究計劃簡介 | Available Patent 可授權專利 |

Video demonstration 短片介紹:

Copyright © 2014 Faculty of Engineering, The Chinese University of Hong Kong. All rights reserved.